LAX Automated People Mover

DESIGNERS: HDR, HNTB, DLR Group

GENERAL CONTRACTOR: LINXS

SPECIALTY CONTRACTOR: CMF INC

FACADE AREA: 800,000 SQF

MATERIAL: EVO Aluminum Wall Panel System and Anova Aluminum Ceiling Panel System

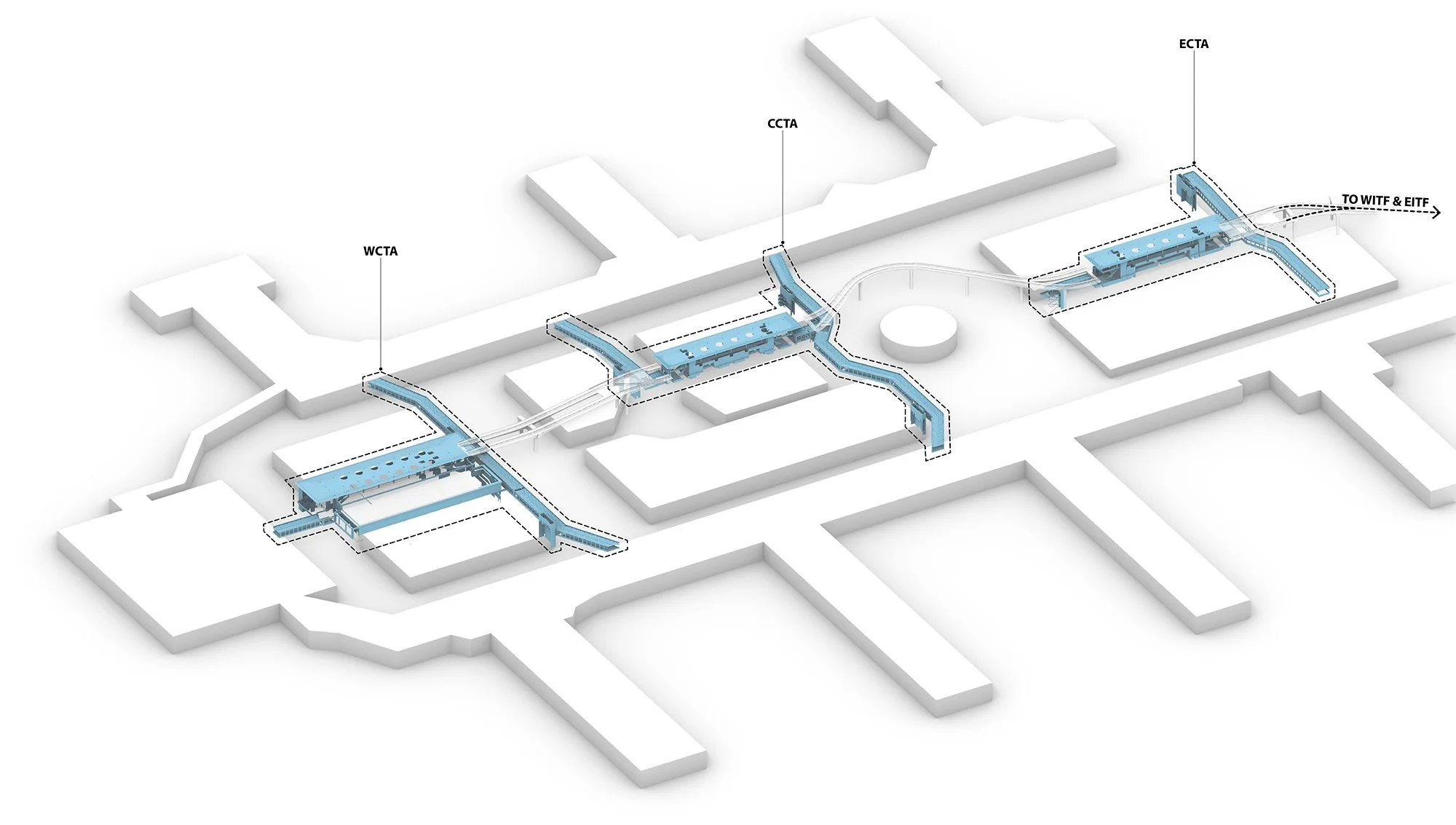

SCOPE: For the Los Angeles International Airport (LAX) Automated People Mover, Neme Design Studio provided advanced façade design consulting and 3D coordination modeling services supporting over 400,000 sq ft of wall metal panels and 400,000 sq ft of ceiling panels across five stations and eight pedestrian walkways.

Our team developed a comprehensive 3D BIM model as the foundation for cross-trade coordination. Only after the digital geometry was validated were façade shop drawings generated directly from the approved model. This ensured perfect alignment between 3D models, 2D elevations, and fabrication details, all sharing consistent reference dimension points for precise coordination.

Each panel within the façade coordination model carried detailed metadata, enabling automated extraction of panel tags, quantities, and dimensions into Excel schedules. Once approved, all panel information was exported to CNC machines—streamlining production, saving time, and minimizing human error in the drafting of the fabrication layouts of the complex metal panel façade system.

Through this integration of digital fabrication for architecture, BIM façade modeling, and construction-phase façade support, Neme Design Studio optimized accuracy, efficiency, and quality for one of Los Angeles’ most high-profile transportation projects.

LOCATION: Los Angeles, CA